Feel the Power: Students in Freshman-level Course Create Extra Credit Projects That Illustrate Electricity at Work

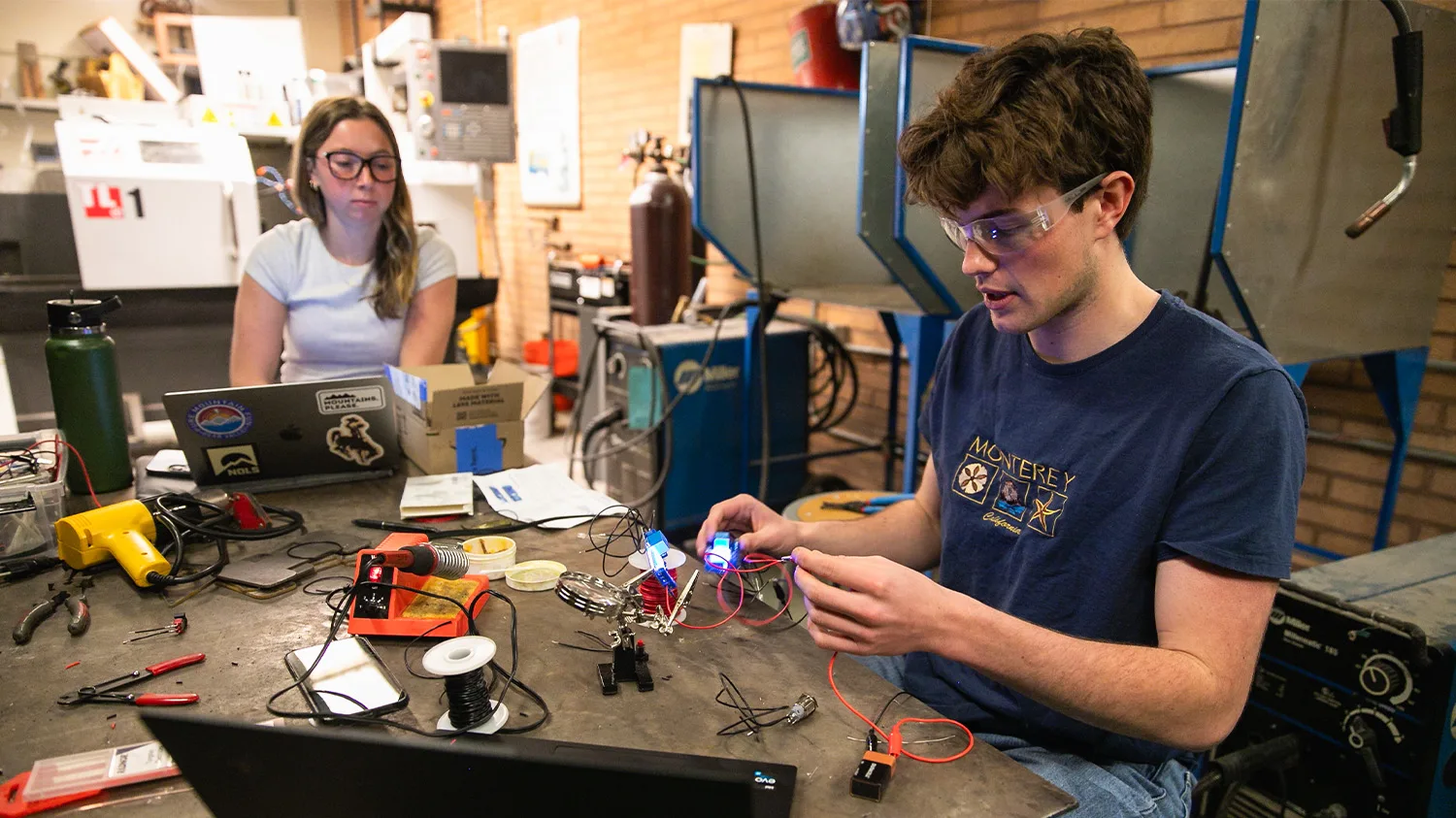

Addy Hulme, left, and Liam Ryan work on a gym interval timer. (Photo/Jahan Ramezani)

Standing at the front of an ITP 150 lab, Jack McDermott slowly turns a peg on his electric Fender guitar.

Next to him, project partner Michael Gallo holds a tuner the two students created using a 3D printer. When the Fender’s low E note is in tune, a green light illuminates on the tuner, marking a successful demonstration.

“We both like guitar,” Gallo said later. “So we decided to do something like this.”

Students in Tyler Blumer’s freshman-level Industrial Technology and Packaging class learn about industrial power, with topics that include pneumatics, hydraulics, mechanical levers and sustainable power. Sometimes the students even take apart small engines.

Jack McDermott, left, and Michael Gallo demonstrate the guitar tuner they created to their ITO 150 class (Photo/Pat Pemberton)

To get students more excited about the topics, Blumer offers them the opportunity to perform a Learn by Doing extra credit project demonstrating what they learn in class.

“The best way that students learn is when they can apply the lessons they’re learning in the class to something they’re passionate about outside the class,” said Blumer, a lecturer and Cal Poly alumnus with a decade of industry experience. “We’ve got students making guitar amplifiers, we’ve got students making robotic arms. I had a group do an interval timer to use at the gym to know how long to work out and how long to rest.”

The Dean’s Excellence Fund helps fund projects like the ones students are pursuing in this class. please consider supporting Learn by Doing.

Students who pursue the extra credit have to submit a 1-page proposal in which they propose what they want to create, what parts are needed and a risk assessment. There aren’t many rules, though making weapons is forbidden.

“As long as they’re not dangerous or unethical, I’m pretty much giving them the green light to make it,” Blumer said.

If parts are expensive, Blumer can help them obtain funds from the college’s discretionary fund.

After considering remote controlled cars, drones and wireless bike brakes, Scott Betterly and Nathan Briar created a smart mirror for their project.

“We wanted to do something ambitious where we learned something,” Briar said.

Lecturer Tyler Blumer, left, talks with student Jordi Rodriguez about a small engine in the ITP 150 course he teaches. (Photo/Pat Pemberton)

A smart mirror is a 2-way mirror with a display behind it that is typically used to show useful information. That can be a calendar, weather, a local surf report, baseball scores and more.

To make it work, the two used the operating system Rasbian.

“It turned out to be almost more of a computer science project,” Betterly said. “It took us a while to figure out the coding.”

During their presentation, the mirror displayed the reflection of seated classmates, along with a message: “Looking good.”

“I think the Learn by Doing philosophy of Cal Poly really shows here,” Betterly said.

McDermott and Gallo had also considered a project that would have entailed more programming – creating a guitar effects pedal. But they ultimately chose to build a tuner, which features lights, input jacks, and a switch.

“And just a ton of wires going everywhere,” McDermott said.

The tuner they created isn’t as good as one you might buy at a store, Gallo conceded. “But the point of the project is more about figuring it out.”

Since Blumer first began encouraging the extra credit projects a year ago, he has witnessed impressive results.

“I’ve seen students getting into some really complex stuff,” he said. “They’re figuring out how to write computer code, largely on their own. They’re testing it. They’re learning how to use micro-controllers and sensors and relays. They’re picking it up really fast.”